The various starting methods of induction motor which are employed to restrict the initial rush of current in squirrel cage induction motors are given below:

Starting Method of Induction Motor

- Direct on Line Starter

- Star/Delta Starter

- Autotransformer Starter

Direct on Line Starting Method of Induction Motor

In this starting method of induction motor, the motor is switched on direct to the supply mains by switching contactor. This operation results in a heavy rush of motor current. This high current rapidly decreases as motor picks up speed but it is at very low power factor thus it tends to disturb the voltage of the supply in the distribution lines.

For this reason, this starting method of induction motor is normally limited to small induction motors (up to 5 H.P). Starting torque obtained by this method is higher than that of the auto transformer or star-delta starter.

A direct on line starter essentially consists of a contactor having four normally open (NO) contacts. The contactor coil is called no-volt coil. There are two push buttons Start and OFF which are used for starting and stopping the motor.

To start the motor, the Start push button is pressed which energizes the contactor coil by connecting it across R and Y phase. The no-volt coil pulls its plunger in such a direction that all the normally open contacts are closed and the motor is connected across supply through three contacts.

The fourth contact A serves as hold on contact which keeps the no-volt coil circuit complete even after the Start push button is released. To stop the motor OFF push button is pressed momentarily which de-energizes the no-volt coil thus opening the main contacts.

When the motor is overloaded, the thermal overload contact, connected in control circuit opens thus disconnecting no-volt coil from the supply. Overload protection is achieved by thermal overload relays.

This works on the principle that if the current is more than normal more heat is generated a thermal element through which the motor current passes. When the motor current reaches a predetermined value the heat generated deflects strip thereby opening the control circuit and the motor does not get the supply.

Star Delta Starting Methods of Induction Motor

This method is based on the principle that in star connections, the voltage across each winding is phase voltage i.e. 1/√3 times the line voltage whereas the same winding, when connected in delta, will have full line voltage across it.

So at the time of start connections of the motor are made in star fashion so that reduced voltage is applied across each winding. After motor attains speed the same windings through a changeover switch are connected in delta. The starter is provided with overload and under voltage protection devices.

In this starting method of induction motor starting, torque is reduced to 1/3 of starting torque obtained with direct switching. The star delta starters are very suitable for delta connected motors up to 25 H.P.

Auto Transformer Starting Methods of Induction Motor

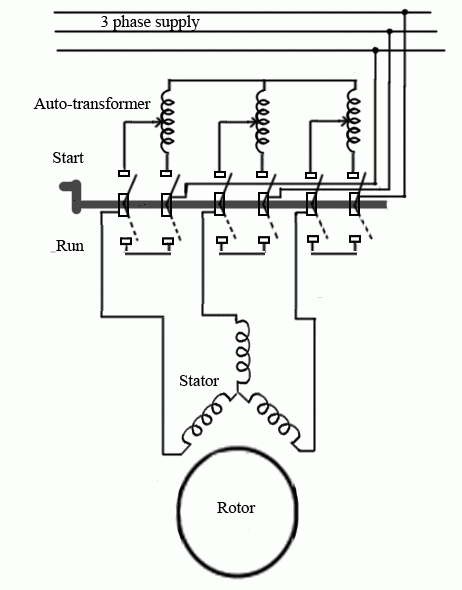

In an autotransformer starter, a reduced voltage is obtained by means of an autotransformer is connected in series with each stator phase. As the current flows through the autotransformer a voltage drop occurs which causes a reduced voltage across motor terminals.

At the time of start, less voltage is applied to the motor by a three pole double throw switch. After the motor has accelerated to about full speed, the operating handle is moved to run position. Overload protection and under voltage protection is provided as explained in DOL stating method of induction motor.

Though this type of starter is expensive but is most suitable for the star connected and delta connected induction motors. Moreover, the voltage applied to the stator at the start can be reduced to any suitable value, therefore this starting method of induction motor is most suitable for large induction motors (above 25 H.P.).

Let the motor be started by an autotransformer having transformer ratio K.

Starting torque = K2 x torque obtained by direct switching.

Starting Method of Slip Ring Induction Motor

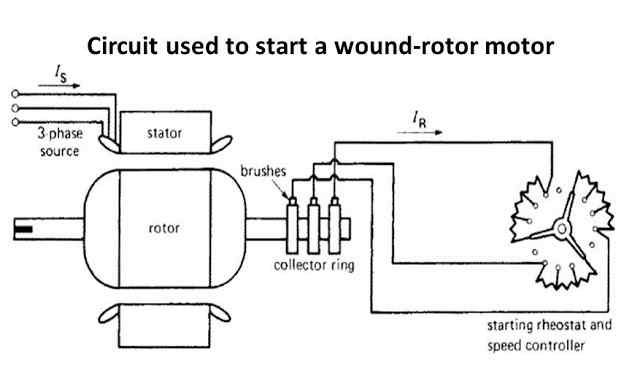

To start a slip ring induction motor, a three phase rheostat is connected in series with the rotor circuit through brushes as shown in the figure. This is known as rheostat starter. This is made of three separate variable resistances joined together by mean of a three phase armed handle which forms the star point. By moving the handle equal resistance in each phase can be introduced.

At start whole of rheostat resistance is inserted in the rotor circuit and the rotor current is reduced correspondingly it reduces the current drawn by the motor at start.

When motor picks up speed the external resistance is reduced gradually and ultimately the whole of the resistance is taken out of circuit and slip rings are short-circuited.

By this starting method of induction motor not only the starting current is reduced but at the same time starting torque is increased.

Thanks for reading about “starting methods of induction motor”.

Three Phase Induction Motor | All Posts

- Three Phase Induction Motor Construction

- Rotating Magnetic Field in Three Phase Induction Motor

- Three Phase Induction Motor Working Principle

- Induction Motor Slip

- Torque Formula for Induction Motor

- Torque Slip Characteristics of Induction Motor

- Losses in Induction Motor

- Induction Motor Tests

- Double Squirrel Cage Induction Motor

- Speed Control of 3 Phase Induction Motor

- What is a variable frequency drive?

- Autotransformer Starter Working Principle

- Thermal Overload Relay Working

- Induction Motor Equivalent Circuit

- Linear Induction Motor Working | Applications

© https://yourelectricalguide.com/ starting methods of induction motor.