Standard Types of Squirrel Cage Motors

Different types of 3-phase squirrel-cage motors have been standardized, according to their electric characteristics, into six types, designated as design A, B, C, D, E and F respectively. The original commercial squirrel-cage induction motors which were of shallow slot type are designated as class A.

For this reason, Class A motors are used as a reference and are referred to as ‘normal starting-torque, normal starting-current, normal slip motors.

- Class A – Normal starting torque, normal starting current, normal slip

- Class B – Normal starting torque, low starting current, normal slip

- Class C – High starting torque, low starting current, normal slip

- Class D – High starting torque, low starting current, high slip

- Class E – Low starting torque, normal starting current, low slip

- Class F – Low starting torque, low starting current, normal slip

Class A Motors

It is the most popular type and employs squirrel cage having relatively low resistance and reactance.

- Its locked-rotor current with full voltage is generally more than 6 times the rated full-load current.

- For smaller sizes and number of poles, the starting torque with full voltage is nearly twice the full-load torque whereas for larger sizes and number of poles, the corresponding figure is 1.1 times the full-load torque.

- The full-load slip is less than 5 percent.

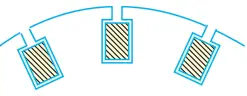

The general configuration of slot construction of such motors is shown in Fig. 1. As seen, the rotor bars are placed close to the surface so as to reduce rotor reactance.

Such motors are used for fans, pumps, compressors and conveyors etc. which are started and stopped frequently and have low inertia loads so that the motor can accelerate in a few seconds.

Class B Motors

These motors are so built that they can be started at full-load while developing normal starting torque with relatively low starting current.

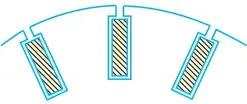

Their locked-rotor current with full voltage applied is generally 5 to 5 1/2 times the full-load current. Their cages are of high reactance as seen from Fig. 2.

The rotor is constructed with deep and narrow bars so as to obtain high reactance during starting.

Such motors are well-suited for those applications where there is limitation on the starting current or if the starting current is still in excess of what can be permitted, then reduced voltage starting is employed.

One of the common applications of such motors is large fans most of which have high moment of inertia. It also finds wide use in many machine tool applications, for pumps of centrifugal type and for driving electric generators.

Class C Motors

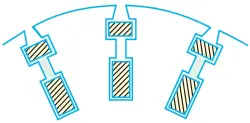

Such motors are usually of double squirrel-cage type (Fig. 3) and combine high starting torque with low starting current.

- Their locked-rotor currents and slip with full voltage applied are nearly the same as for class B motors.

- Their starting torque with full voltage applied is usually 2.75 times the full-load torque.

For those applications where reduced voltage starting does not give sufficient torque to start the load with either class A or B motor, class C motor, with its high inherent starting torque along with reduced starting current supplied by reduced-voltage starting may be used.

Hence, it is frequently used for crushers, compression pumps, large refrigerators, coveyor equipment, textile machinery, boring mills and wood-working equipment etc.

Class D Motors

Such motors are provided with a high-resistance squirrel cage giving the motor a high starting torque with low starting current.

- Their locked-rotor currents with full voltage applied are of the same order as for class C motors.

- Their full-load slip varies from 5% to 20 per cent depending on the application.

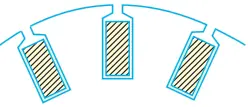

Their slot structure is shown in Fig. 4. For obtaining high starting torque with low starting current, thin rotor bars are used which make the leakage flux of the rotor low and the useful flux high.

Since these motors are used where extremely high starting torque is essential, they are usually used for bulldozers, shearing machines, punch presses, foundry equipment, stamping machines, hoists, laundry equipment and metal drawing equipment etc.

Class E Motors

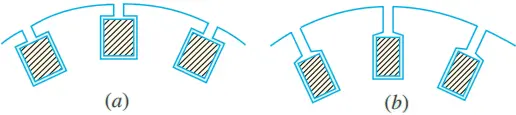

These motors have a relatively low slip at rated load. For motors above 5 kW rating, the starting current may be sufficiently high as to require a compensator or resistance starter. Their slot structure is shown in Fig. 5 (a).

Class F Motors

Such motors combine a low starting current with a low starting torque and may be started on full voltage. Their low starting current is due to the design of rotor which has high reactance during starting [Fig. 5 (b)].

The locked rotor currents with full voltage applied and the full-load slip are in the same range as those for class B and C motors.

The starting torque with full voltage applied is nearly 1.25 times the full-torque.