Extensions of Thermocouple

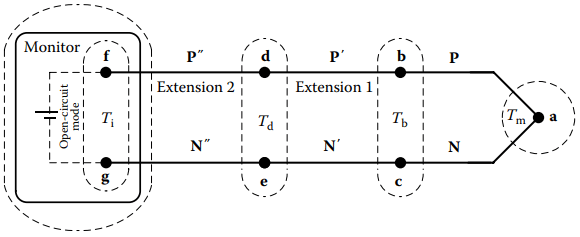

In the Figure given below, pairs P′N′, P″N″ and any additional thermoelement pairs are optional circuit extensions. A connector is an extension. Every thermoelement must be homogeneous. Only two junctions may function as the essential reference junctions. Which two depends on the type of extensions?

If there are no extensions, b and c are the reference junctions and are directly connected to the instrument terminals. In most practical applications, the PN measuring thermocouple must be remote from the monitor. In such cases, extension legs P′ and N′ (and any additional ones) might be either similar to or very different in Seebeck characteristic from continuous thermoelements P and N and from each other. Extension leads are of three types:

(1) passive, (2) corresponding, and (3) compensating.

These types serve different applications. All extension styles are commercially available. Some are proprietary.

Passive-Type Extensions of Thermocouple

The positive and negative legs of passive-type extensions are alike in Seebeck characteristic. As they are alike, they are intended to contribute no significant emf. Usually both legs are of un-plated electrical grade copper, but any conductor could be used.

If all extensions are of passive type, reference temperature compensation is applied only at isothermal reference junctions b and c of thermocouple, PN.

Compensation must not additionally be applied at the monitor terminals. As junctions f and g at the monitor are often remote from junctions b and c of the measuring thermocouple, they usually are at very different temperatures.

With passive extensions, if compensation incorrectly were applied at instrument terminals f and g, essential Seebeck emf from the temperature interval between Tb and Ti would be missing causing substantial error. Passive leads often are used with the dual-reference junction circuit in precision calibration.

An accurate 0°C reference temperature can be applied to reference junctions b and c by a fixed-point physical temperature reference such as a precision ice bath. Inappropriate emf contributions of other thermoelements are eliminated.

For passive extensions, the temperature value at incidental junctions, such as d and e, does not matter if they are isothermal.

Two other kinds of extension leads are corresponding and compensating types. They are used where compensating voltage is to be provided by the monitor. For these two styles, the paired extension thermoelements are essential contributing sources of emf.

Commercial corresponding- or compensating style leads, as a pair, are of the same nominal thermocouple characteristic as the principal thermocouple but usually they are un-calibrated.

Corresponding-Type Extensions of Thermocouple

Each leg of corresponding-type extensions and connectors for base-metal thermocouples has an absolute Seebeck coefficient of the same nominal type as the corresponding leg of the thermocouple. Corresponding-type extensions contribute emf.

They are used with base-metal thermocouples, particularly those many measuring thermocouple assemblies specialized for diverse applications. Extensions can be of thermocouple-grade material. If of extension grade, they might have a broader tolerance and match over a narrower temperature range than the PN thermocouple.

Corresponding extensions usually are not calibrated. If all extensions are of the corresponding type, reference junctions must be at terminals f and g. They must be isothermal. Extension leads for refractory or precious metal thermocouples are of compensating style rather than corresponding type.

Compensating-Type Extensions of Thermocouple

The third extension type also is intended to contribute emf. This compensating style is used for economy and convenience to extend costly precious or refractory metal thermocouples that are necessary for measuring very high temperatures and for some environments.

Compensating-type extensions can have positive legs that are of different Seebeck coefficient than positive leg P and also from other linked positive extension legs. Likewise, negative extension legs are all not like N. Rather, each paired compensating extension must have the relative coefficient of each extension, as a pair, approximate the σPN of the PN pair.

Usually, only a short length of costly precious or refractory metal measurement thermocouple material has to be exposed to the adverse environment. Extensions can be less costly, insulated differently from the thermocouple, can add bulky shielding and mechanical protection, and can extend a great distance to a recording facility.

Often, compensating extensions are made for much higher temperatures than are corresponding-type extensions. However, accuracy is degraded if extensions are used to the higher allowed temperatures because more of the emf is from the compensating extensions than would be from corresponding extensions limited to lower temperature.

Mixed Type Extensions of Thermocouple

One or more passive extension pairs and connectors can be used in series with multiple extensions of the corresponding or of compensating types. All emf-supplying extensions and connectors must be nearer the measuring thermocouple than any passive extension. Mixed corresponding and compensating extension pairs can be connected.

However, all passive extensions must follow all emf-supplying extensions and must connect to the monitor. The only reference junctions are of the final pair of the emf-contributing corresponding-type or compensating-type extensions.

The monitor must not apply additional compensating voltage if the last extension is of passive style. It is essential that the incidental junctions at each end of every extension be isothermal.

Related Posts

- Thermocouple Working Principle

- Absolute Seebeck Effect

- Basic Thermocouple Circuits

- Extensions of Thermocouple

- Functional Model of Thermoelectric Circuits

- T/X Sketch of Dual-Reference Junction Circuit

- Applications of Functional Model

- Characteristics of Thermocouples

- Thermocouple Hardware

- Thermocouple Junction Styles

- Active Tests of Thermocouple

- Calibration of Thermocouples

- Thermocouple Thermometry Practice

- Distinctive Thermocouple Noise Problems