Since a synchronous motor is inherently not self-starting, the following synchronous motor starting methods are adopted generally:

Synchronous Motor Starting Methods

Pony Motor Starting Method: In this method, a small induction motor known as pony motor is used to bring the motor speed to synchronous speed. After the speed has reached up to its synchronous value, the DC field is switched ON. The motor gets synchronized, and then supply to the pony motor is disconnected. In some systems, pony motor is mechanically decoupled.

The starting of a synchronous motor by pony motor has the advantage of low in-rush current at the start. Since, the starting motor is of much smaller size. The pony motor is provided with a pair of poles less than the synchronous motor.

Damper Winding Starting Method: It is the most common starting method of synchronous motor. In this method, the motor is started as a squirrel cage induction motor by providing a special winding on the rotor poles called damper winding.

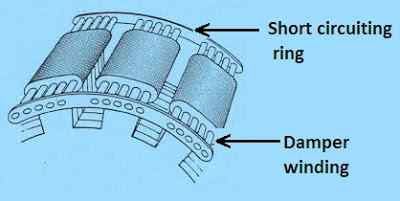

The damper winding is an additional winding included on the rotor side. The construction of the damper winding is shown in the Figure. This damper winding consists of several copper bars embedded into the holes provided on the outer periphery of the rotor and then short-circuiting these bars by brazing them to end rings. This construction is similar to that of the squirrel cage rotor of an induction motor.

When the synchronous motor is connected to the three-phase supply, the motor starts as a squirrel cage induction motor. As soon as it attains about 95% of synchronous speed, the rotor winding is connected to DC mains, and the rotor field is locked with stator field, and the motor runs as a synchronous motor.

When the rotor is rotating at synchronous speed, the relative velocity between the RMF (rotating magnetic field of the stator) and the rotor is zero. Hence the induced EMF and current in damper winding are zero. Therefore damper winding is ineffective when the rotor is rotating at synchronous speed, but we can use the damper winding for starting the motor. Thus damper winding allows the synchronous motor to be started as a squirrel cage motor and makes it self-starting.

When started as an induction motor, the methods of starting are the same as for induction motors, i.e., direct-on-line and reduced voltage starting methods. The motor draws several times its rated current at a low p.f. during starting, which may necessitate starting by reduced voltage methods. Where the starting torque is heavy, the motor is provided with a wound-rotor to be started as a slip-ring induction motor.

The field is closed through resistance at the time of starting. It is connected to the DC source only when the motor has come up to the speed. The application of field current can be manual or automatic.

Synchronous Motor Starter

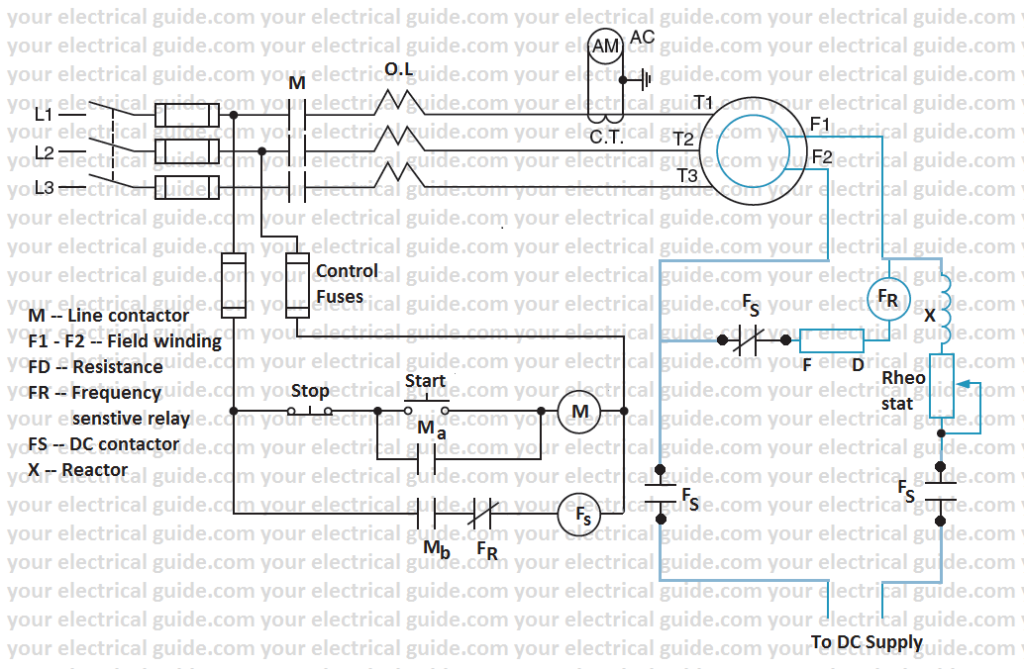

The Figure given below shows an arrangement with direct-on-line starting and automatic application of the field by a frequency-sensitive relay FR.

When the motor is started by pressing the ‘start’ button, Ma and Mb close and current at line frequency is induced through the motor field. This current flows through relay FR as reactor X offers high impedance and through discharge resistance FD. The relay FR picks up rapidly, keeping the control circuit of contactor FS open.

As the motor speed increases, the frequency of induced current through the field winding decreases, with the result that increasing the portion of current flows through reactor X till, near synchronous speed, there is not enough current through the relay FR to hold it. The relay FR opens, the field gets disconnected from the discharge resistance and is connected across the DC bus. The motor now pulls into synchronism.

It may be remembered that a synchronous motor will fail to start if its field is not shorted through a suitable resistance during starting. Also, if the field circuit opens due to any reason, the motor will be damaged. It is, therefore, essential to maintain the field circuit, collector rings, and carbon brushes in good condition.

Why is synchronous motor not self starting?

Assume the number of poles of stator P = 2, then the synchronous speed of the RMF will be = 3000 RPM.

So the stator poles N1 and S1 are rotating at a speed of 3000 RPM i.e., very rapidly in the clockwise direction.

Initially (at the start), the rotor is in an arbitrary position, as shown in Figure. We assume that any other prime mover is not driving the rotor.

The Figure shows the situation at an instant ‘A.’ The rotor is in an arbitrary position. The stator poles S1 and N1 are rotating in the clockwise direction.

The standstill rotor experiences a torque in clockwise direction due to the force of repulsion between the like poles N1 – N2 and S1 – S2.

The rotor takes time to accelerate in the clockwise direction due to inertia. Before the rotor can accelerate in the clockwise direction, the stator poles change their polarity quickly.

At the instant ‘B,’ which occurs a period half after instant ‘A,’ the stator poles have acquired new polarity, but the rotor is still in the previous position.

Now, the standstill rotor experiences a torque in anticlockwise direction due to force of attraction between unlike poles N1 – S2 and S1 – N2.

Thus, in the case of a synchronous motor, standstill rotor is subjected to a torque which is changing its direction at a very high speed, the rotor cannot respond to it due to its inertia and hence remains stationary.

Thanks for reading about the starting methods of synchronous motor and synchronous motor starting methods.