Before discussing the speed control of dc shunt motor, we have to find the factors affecting the speed of a DC motor. The speed equation of a DC motor shows that,

N α Eb / φ

or N α (V – IaRa)/ φ

But the resistance of armature winding is small. Therefore the voltage drops IaRa will be negligible as compared to the external supply voltage V. Therefore, the expression for the speed can be approximated as follows:

N α V/φ (because V>> IaRa)

From this expression we can obtain the dc shunt motor speed control methodsas follows:

- The speed is inversely proportional to flux φ.

- It is directly proportional to armature voltage drop (IaRa).

- It is directly proportional to applied Voltage V.

Speed Control of DC Shunt Motor

So by varying one of these parameters, it is possible to change the speed of DC shunt motor. Depending on the parameter being controlled, methods of speed control of shunt DC Motor are classified as follows:

Flux Control Method

The set up for speed control of DC shunt motor using flux control technique is shown in the figure. In order to change the speed, we have to change flux. This can be achieved by changing the field current. The field current can be changed by changing the rheostat R connected in series with the field.

At the time of starting the motor, we need to run the motor slowly, therefore, the flux should be maximum, because,

N α 1 / φ

To obtain maximum flux at the start, the field current should be maximum at the time of starting. To obtain this, the value of rheostat (R) should be minimum.

The speed of DC shunt motor can be varied by varying the field current. As we increase the resistance R of the rheostat, the field current Ish decreases. So the flux φ decreases. This results in increasing the speed of the motor. As the R is increased, the speed increases.

We can use this technique to control motor speed above its rated value. It is the most commercial method. There is a limit to the maximum obtainable speed by this method due to poor commutation at week fluxes. Most common maximum to minimum speed ratio is 6:1.

Speed Control of DC Shunt Motor by Armature

The set up for speed control of DC shunt motor by armature voltage control method is shown in the figure. A rheostat is connected in series with armature winding. By varying the value of R we can vary the voltage across the armature.

Because speed N is directly proportional to armature voltage, it is possible to change the speed by changing the value of rheostat R.

We can use this technique to control motor speed below its rated value. But it is neither efficient nor economical method because, in this method, speed is reduced at the cost of power loss in rheostat (Ia2R).

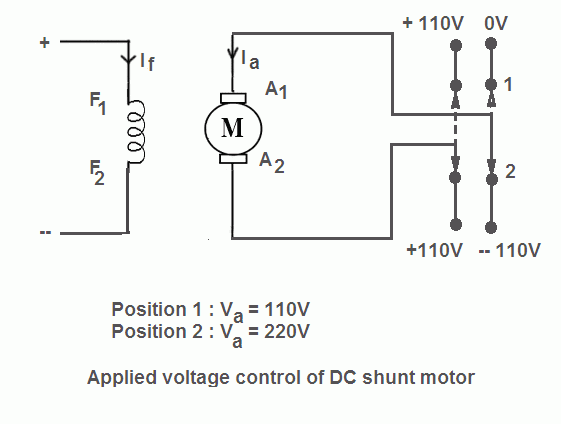

Speed Control of DC Shunt Motor by Applied Voltage

In this method, the field winding of the motor is connected to a constant DC voltage. But armature is supplied with different voltages with the help of suitable switch gear as shown in the figure.

Advantages

- The biggest advantage of this method is that the direction can be reversed.

- Smooth increase and decrease in speed are possible.

- The speed control can be obtained over the wide speed range.

Disadvantages

The arrangement for changing the applied voltage is expensive.

Speed Control of DC Shunt Motor by SCR

The figure shows an SCR circuit that can be used for the speed control of dc shunt motor. In this circuit, the supply voltage to the armature can be varied by varying the conduction angle of the SCR, so the smooth variation in speed is possible.

Here the diac is used to trigger the SCR. The bridge rectifier is used for full-wave rectification. The field winding is connected across the pulsating output and voltage to the armature is controlled by varying R2.

At the end of each cycle capacitor, C is completely discharged. The capacitor begins to charge in each cycle through resistance R2, diode D2, and the armature winding.

When the capacitor is charged up to the breakdown voltage of diac, a trigger pulse is delivered to the SCR gate turning it ON. The pulsating voltage is applied to the armature.

The SCR is turned OFF at the end of each half-cycle, when the anode current will be less than the holding current. At the end of each half-cycle capacitor discharges through D1, R1 and field winding i.e. at the beginning of each cycle, the capacitor voltage is zero.

The time taken by the capacitor C1 to charge up to the breakdown voltage of diac is controlled by the resistance R2. If R2 is lower the firing angle will be small means the more voltage will be applied across the armature i.e. if R2 is low the motor speed will be high, if R2 is high the motor speed will be low.

The diode D3 is a freewheeling diode. To know about its function please follow the link.

Speed Regulation

This circuit provides the automatic speed regulation against the supply and load variation.

When the motor starts running it develops back EMF. The time required by the capacitor to charge up to the breakdown voltage of the diac will depend upon R2 and the voltage across the SCR. The voltage across SCR is the difference between the bridge output and the back EMF.

If speed is high, back EMF will be high, and the voltage across SCR will be low. In this case, the capacitor will charge up to the diac breakdown voltage in more time. If the speed is low, back EMF will be low, so the voltage across SCR will be high and the capacitor can charge up to the diac breakdown voltage in less time.

If the load is increased motor speed will reduce, reducing the back EMF. The voltage across SCR will increase, reducing the firing angle. If the firing angle is reduced, more voltage will be applied to the armature. So the reduction in speed will be compensated and the motor will run at the predetermined speed.

If the load is reduced, the speed will increase, increasing the back EMF. The voltage across the SCR is reduced, increasing the firing angle. The voltage applied to the armature of the motor is reduced which means the motor speed will be reduced to the predetermined value.

Related Posts

- Construction of DC Motor | Machine

- Working Principle of DC Motor

- Types of DC Motor

- Speed Control of DC Motor

- Speed Control of DC Shunt Motor

- Speed Control of DC Series Motor

- Characteristics of DC Motor

- Electric Braking of DC Motor

- BLDC Motor Working Principle

- Operation of BLDC Motor

© https://yourelectricalguide.com/ DC Shunt Motor Speed Control Methods.