Hi friends, in this article, I am explaining the SF6 circuit breaker working principle and construction. This article will increase your knowledge; I hope so.

In the oil circuit breakers, air circuit breakers and low oil circuit breakers, arc extinction take place slowly after the moment of contact separation. Hence, the arc is usually extinguished after a few half cycles of current have passed zero.

Quick arc extinction requires a high dielectric strength of the arc path and its fast recovery after current zero instant. In the case of H.V. circuit breakers, it is essential. SF6 circuit breakers and vacuum circuit breakers have batter properties in this regard as compared to other circuit breakers.

Therefore, nowadays SF6 circuit breaker and the vacuum circuit breaker is preferred in H.V. systems over other conventional circuit breakers. The oil circuit breakers, air circuit breakers and low oil circuit breakers are becoming outdated now.

SF6 Circuit Breaker Working Principle & Construction

We can divide an SF6 circuit breaker into two units, namely:

- Interrupter unit

- The gas system

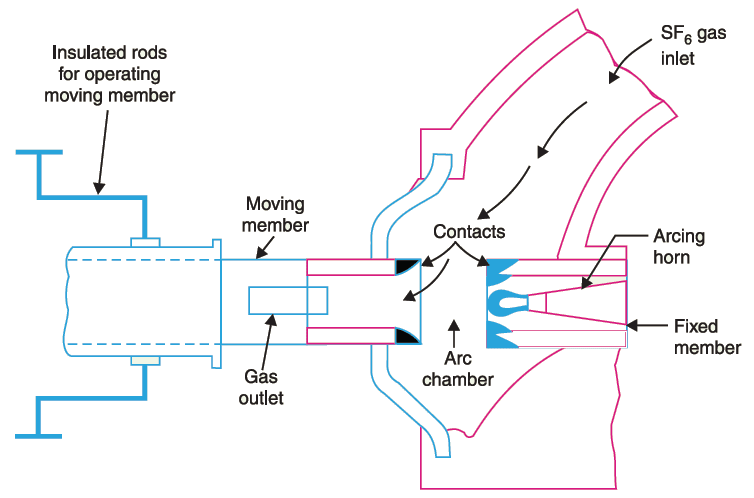

Interrupter Unit: This unit consists of moving contacts and fixed contacts in a chamber filled with SF6. The fixed contact is hollow cylindrical contact comprising an arcing horn.

The moving contact is also a hollow cylindrical contact with holes in its sides known as side vents. Side vents in the moving contact permit the high-pressure gas into the main tank after flowing along and across the arc.

When moving contact is withdrawn from fixed contact an arc is struck between contacts. The SF6 gas is blown axially along the arc by the gas system of the breaker. The gas is made to flow from a high-pressure zone to a low-pressure zone through a nozzle.

The nozzle is located such that the gas flows axially over the arc length. The heat is removed from the arc by axial convection and radial dissipation. This reduces the arc diameter, and the arc is extinguished at current zero instant.

The Gas System: A closed-circuit gas system is used in the SF6 circuit breaker. SF6 is a costly gas. Therefore, it is renovated and recycled after each operation of the breaker. The necessary auxiliary system is made for such purpose. The gas is stored in a high-pressure chamber at 16 atmospheres whereas the gas pressure at the low side is 3 atmospheres.

The breaker also has an alarm system. The alarm system gives a warning if the gas pressure drops below a certain value and safety system immobilize the breaker if gas pressure reaches up to a danger limit. Because at low pressure, the dielectric strength of SF6 gas is reduced, which decreases its arc quenching ability.

Sealing is done very carefully to prevent gas leakages at joints. A heater is provided in the high-pressure chamber to avoid the liquefaction of gas at low temperature, which maintains its temperature at 200C.

Why SF6 gas is used?

We use SF6 gas in circuit breakers due to its unique electrical and chemical properties. These are as under:

1. It is a chemically stable and inert gas and does not react with materials used in SF6 circuit breaker construction. The life of metallic parts, contacts is longer is SF6 gas.

2. The dielectric strength of SF6 gas is 2.35 times that of air and less than that of dielectric oil at atmospheric pressure. By increasing the pressure, its dielectric strength can be made more than that of dielectric oil. Therefore, by using the SF6 gas at high pressure, size of the SF6 circuit breaker can be reduced.

3. The ability of an atom to attract and hold electrons is known as its electronegativity. The SF6 gas is highly electronegative. Due to which SF6 gas quickly absorbs free electrons form an arc and forms negative ions.

These negative ions are relatively heavier and immobile as compared to free electrons. Therefore, these are ineffective as a charge carrier. So, ionized SF6 gas has high dielectric strength as unionized gases of the same density.

Therefore, the SF6 gas not only posses a good dielectric strength but regains its dielectric strength rapidly after final current zero due to its electronegativity and low time constant. Time constant is the time between current zero and the instant when the conductance of contact spaces attains zero value.

However, moisture decreases properties of SF6 gas remarkably.

Advantages of SF6 Circuit Breakers

SF6 circuit breakers have the following advantages over OCB, ACB and MOCB:

- Outstanding insulating, arc extinguishing, and chemical properties of SF6 gas is an additional benefit of SF6

- This gas and its decomposed products are non-inflammable, i.e. there is no risk of fire or explosion.

- Electrical clearances are very much reduced due to the high dielectric strength of SF6

- Short arcing time and excellent arc quenching properties of SF6 gas reduce the wear and tear of contacts.

- Due to its sealed construction, its performance is not affected by atmospheric conditions.

- SF6 circuit breakers are used in H.V. systems from 72 to 550 kV for interrupting fault current of 20 to 63 kA at the rated current of 1200 – 12000 A.

Problems with SF6 Circuit Breaker

- Gas sealing problems.

- Ingress of moisture in the circuit breaker is very harmful.

- Special facilities are required to maintain the quality of gas and its transportation. Poor quality of gas affects performance and hence reliability of the SF6 circuit breaker.

Thanks for reading about “SF6 circuit breaker working principle”. For more details, visit Wikipedia.