Hi friends, in this article, I am going to discuss the lightning arrester types and lightning arrester working principle. You will find this article very interesting and informative, I hope so.

The lightning arresters are used to protect the power system from high voltage surges. An arrester does not absorb lightning or stop lightning. It diverts the lightning, limits the voltage, and protects the equipment installed in parallel.

In AC systems, they can be used to protect almost everything like transformers, generators, circuit breakers, bus bars, etc. Whereas in HVDC systems, they are mainly used to protect the filter, unit reactor, and buses.

Lightning Arrester Types

The most commonly used lightning arrester types are as under:

- Rod gap arrester

- Horn gap arrester

- Multi gap arrester

- Expulsion type lightning arrester

- Valve type lightning arrester

- Metal oxide varistor lightning arrester

Lightning Arrester Working Principle

When a voltage surge traveling along the conductor reaches the point at which a lightning arrester is installed it breaks down the insulation of the arrester momentarily, allowing the voltage surge to discharge to the ground.

As soon as the system voltage drops below the predetermined value, insulation between the conductor and ground is restored and further current flow to the ground stops. To perform this protective function satisfactorily, arresters must:

- Not allow current to flow to the ground as long as the system voltage remains normal.

- Provide a path to the ground, when the system voltage rises to a predetermined valve above normal, to dissipate the energy from the surge without raising the voltage at which the circuit is operating.

- Stop the flow of current to the ground, as soon as the system voltage drops below the predetermined value, and restore the insulating qualities between the conductor and ground.

- Not be damaged by the discharge and be capable of automatically repeating discharging process frequently when required.

The performance of any arrester is dependent on a good connection to the ground. Arresters will not function without proper ground; they are totally useless. The arrester should be placed as close as possible to the equipment, that is to be protected, and leads connecting arresters to the ground should be kept as short as possible. It is connected across the line and the earth terminal. A separate arrester is used for each line conductor.

Lightning Arrester Types

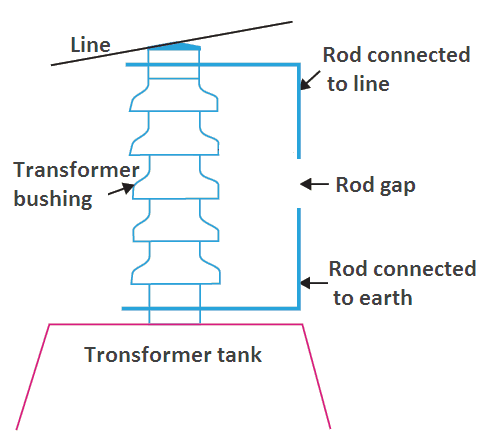

Rod gap Lightning Arrester: It is the simplest type of lightning arrester. It consists of two-rod electrodes, one of which is connected to the line and the other to the earth. These are generally used to protect the transformers.

Under normal operating conditions, the gap remains non-conducting. When a high voltage surge occurs, the gap sparks over, and the surge current is drained to the earth. Such arresters suffer from the following disadvantages:

- The operation is affected by climatic conditions.

- After the surge is over, due to the ionization of air, the arc in the gap is maintained even at the normal supply voltage.

- Increased possibility of bird faults.

- Due to the above disadvantages, the rod gap arresters are used only as a ‘back-up’ protection with main arrestors.

Horn Gap Arresters: A horn gap arrestor has two metal horn-shaped rods fitted on ceramic insulators. The distance between these two rods is adjustable and is adjusted according to the supply voltage.

One side of the arrester is connected to the line through a resistance and choke coil and the other side is connected to the earth properly.

The choke coil provides a low reactance path to fault current at transient frequencies whereas it offers high reactance at normal power frequency. And the choke coil protects the system by draining out the transient current to the earth.

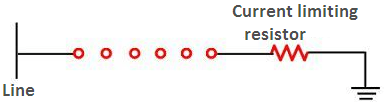

Multi-Gap Arresters: These arresters have a sequence of metal cylinders that are insulated and divided by air gaps with each other. The first metallic cylinder is connected to the line and the last cylinder is connected to the earth by series resistance.

When the transient voltages occur due to a lightning stroke, air between gaps ionizes, corona discharge between cylinders takes place and the transient current is drained to the earth.

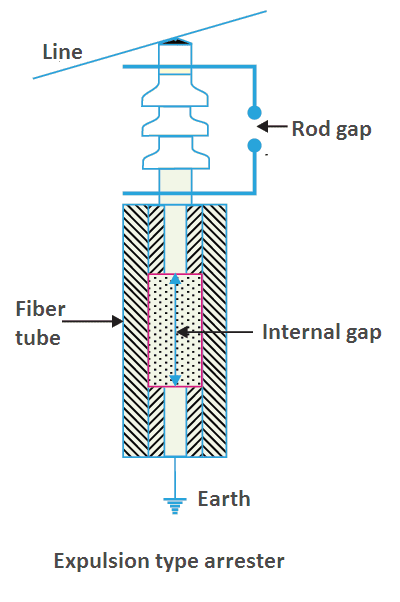

Expulsion Type Lightning Arrester: It consists of an arc extinguishing chamber in series with an air gap. The arc extinguishing chamber is in the form of a fiber tube that interrupts the arc after discharging the surge by the generation of gasses.

When a voltage surge occurs that is sufficient to spark over the series gap and the gap in the fiber tube, the discharge current flows to the ground. The arc in the tube attacks some of the fiber of tube walls, releasing a large amount of a relatively cool, non-conducting gas.

The gas produced in the fiber tube acts not only to extinguish the arc but also builds up high pressure and is expelled through the lower electrode which is hollow. As the gas leaves the tube violently, it wipes out the ionized air around the arc. Due to this strong deionization effect, the arc goes out at the current zero instant and will not be re-established.

An expulsion-type lightning arrester has a current rating in addition to the voltage rating. The maximum current rating must be equal to the short-circuit current available at the point of installation. These are generally used on towers for the protection of transmission lines.

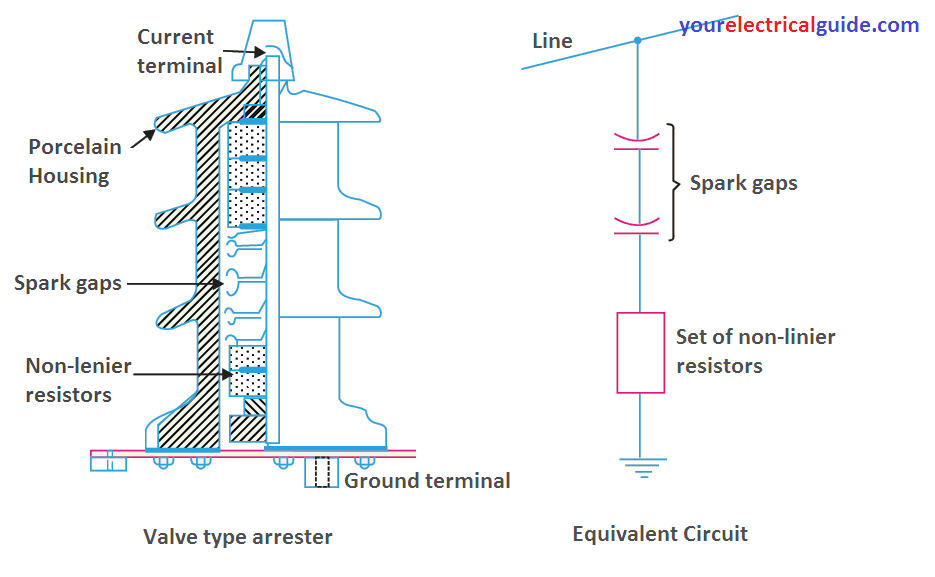

Valve Type Lightning Arrester: It consists of an outer ceramic body containing a set of resistances (valves) and spark gaps in series. The resistances are made of a special silicon carbide ceramic.

It possesses the characteristic of being substantially an insulator at one voltage and then changing to an excellent conductor at a higher voltage; the transition is due to voltage changes only, not to heat as in other valve materials. High-voltage surges spark across the air gap and discharge current flows through the valve to the ground.

Since the valve has a low resistance under high voltage and high resistance at a normal voltage so as soon as system voltage becomes normal current flow stops. The arc gets extinguished and the arrester regains its original state.

The valve-type arrestors are extensively used for the protection of generating stations, sub-stations, overhead lines, cables, and rotating machinery.

They are rated for voltage only and are designated as 70%, 80%, and 100% arresters. The 80% arresters are suitable for solidly grounded systems. Whereas, 100% arresters are used on systems with isolated neutrals or those earthed through impedances. The valve type arresters have been classified into the four types:

- Secondary Type

- Distribution Type

- Line Type

- Station Type

Secondary type lighting arresters are used with medium voltage apparatus, where the equipment is installed in farms and other lightning-prone areas.

Distribution type arresters are used on lines and substations up to 22 kV.

Line type arresters are normally used for voltages up to 66 kV though they can be used for higher voltages also.

Station-type arresters provide the highest degree of protection and should be used where the cost of the protected equipment or the importance of service continuity justifies the extra investment on their account.

Metal Oxide Lightning Arrester: A metal oxide varistor (MOV) lightning arrester consists of a series of metal oxide varistor blocks. These MOV blocks act like voltage-controlled switches.

When the applied voltage across the arrester increases above the rated voltage of the arrester, the MOV starts conducting and excessive energy is drained to the ground. This process continues until the system attains the normal voltage. As soon as the system voltage becomes normal the conduction stops.

The MOV arrester is one of the most commonly used arresters for the protection of the modern power system. They don’t have gaps. This “gap-less” design eliminates the generation of excessive heat during the operation of the arrester.

They give the best performance as the surge voltage conduction starts and stops very quickly at a precise voltage level. This reduces the failure of the arrester and improves system reliability and protection.

When a metal oxide arrester is disconnected from an energized line, it may have a small amount of static charge. Therefore, as a safety precaution, it should be discharged properly by connecting to the ground for a while.

Advantages of Lightning Arrestor

The advantages of lightning arrestors are

- They reduce the damage from lightning strokes.

- They are able to protect the outdoor equipment.

- They reduce the over-voltage surges.

- They reduce electromagnetic interference.

- They are very simple to use.

What is a Lightning Rod?

A metallic rod fitted on the top of the structures like buildings, transmission towers, etc. to protect them from the lighting strikes is known as the lightning rod. It is properly earthed to the grounding system. It provides a safe path to the lightning currents to the ground.

What is a Surge Suppressor?

A surge suppressor is a device installed in the home distribution board to protect the electrical system from voltage surges or switching surges. It is also known as the transient suppressor or surge protector.

The transients due to lightning or switching surges, create spikes in supply voltage. These spikes could harm the electronic devices connected to the supply. A surge suppressor suppresses these spikes and protects our electronic devices.

A surge suppressor has a low voltage rating and low energy dissipation capability. Since the energy level of a lightning stroke is very high, a surge suppressor can’t protect the electrical system from lightning strokes. So the surges due to the lightning strokes can only be suppressed by lighting arrestors.

Thanks for reading about lightning arrester types and lightning arrester working principle. Last Updated on 22-8-23

Related Posts

- Lightning Arrester Types & Working

- Lightning and Switching Voltage Protection Methods

- Personnel Protective Devices

- How Lightning Arrester Works

- Overvoltage Protection by Lightning Arresters

- Insulation coordination of Electrical Equipment

- MCCB Circuit Breakers

- Differential Protection of Generator & Alternator

- Types of Current Limiting Reactor

- Classification | Types of Protective Relays

- Fuse Selection Criteria

- Protection of Transmission lines by Ground Wires